Desde o ano 2000, WayCon é trabalha no desenvolvimento e na produção de sensores Eddu Current em particular para a automação e robótica.

Machine observation - monitoring

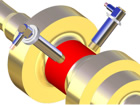

With constantly pursued machines, as for example with turbo-generators in power stations, the state of the bearrings can be supervised. Vibrations beyond the specified area are recognised and the machine can be brought in a reliable operational state, before it comes to cost-intensive and time-luxurious damages.

Furthermore a wear measurement of the main shaft is possible and a servicing interval can be included in the maintenance plan. The behaviour of the rotor can be examined under different load states or with different oleograph in the lubrication gap of the bearrings.

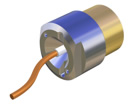

Construction features

The new WayCon-eddy current sensor T10 with 10 mm of measuring range offers sensible detailed solutions for the connection. The sensor can be twisted about a standard-key width SW24. For radial inaccessible situations in thread canals the sensor can be mounted by cylinder drillings and a wide groove without damaging the cable.

TFT-touch-screen – Soon available

Only short time, then the devices of the TX series with TFT-Touch-Screen are available. The generous display offers many interesting possibilities as for example:

- Display of measuring value with the highest resolution

- Adjusting and observing of limit values

- Teach and scaling the displayed value / analog output

- Cash graph with visualisation of the borders

- Graph for rotary shafts with picture of 360°

- Customised linearisation

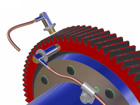

Gear wheel check

For structured surfaces, as for example with gear wheels or groove shafts, we offer the possibility to fade out either the tooth flank by means of software and to spend the average and to receive therefore information about the radial movement, or to grasp the tooth flanks individually in the maximum values.

Here explanation can be received over broken out teeth or shovels or wear. For example, an investigation of the shaft deflection or radial and axial misalignment can be carried out in the vehicle gear with different load states in the test bench or in the driving attempt. Case distortions can be measured.

Main operational area

Main operational area of the eddy current sensors is the check of rotating shafts on imbalance, vibration, unroudness as well as radial and axial runout. For the radial measurement a level coat surface is optimum. Here the relative movement can be measured with a sensor between sensor and shaft. Arranging two sensors in 90 ° corner, one gets differentiated explanation about unroudness and radial runout.

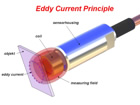

The world of eddy current

The basic measuring principle of the eddy current sensors is based on the fact that the coil generates a magnetic alternating field in the sensor head whose lines of flux leave from the sensor head which pass object, and shut again.

Besides, the measuring field (magnetic alternating field) in the electrically leading-capable object generates the eddy current which entail joule losses. These eddy current losses in the object increase with lower distance.

On the input side of the electronics the eddy current losses about the change of the impedance are evaluated. A output signal proportional to distance is formed as for example 0... 10 V or 4... 20 mA

CMSS

Range: 0,254 - 7,620 mm

Linearidade: ± 50,8 µm

Resolução: 200mV/25,4 µm

Dinamica: 10 kHz

Saida: Analógica

Classe de Proteção: IP 67 IP 68

IC

Range: 0 - 8mm

Linearidade: ± 60 µm

Resolução: 1 µm

Dinamica: 1mm/ms

Saida : Analógica

Classe de Proteção: IP 67

TX

Range: 0,5 - 10,00 mm

Linearidade: +/- 0,25 % v. MB

Resolução: 0,1 µm

Dinamica: 35Khz

Saida: Analógica

Classe de Proteção: IP 67 IP 68